Plastic Banding

PLASTIC BANDING

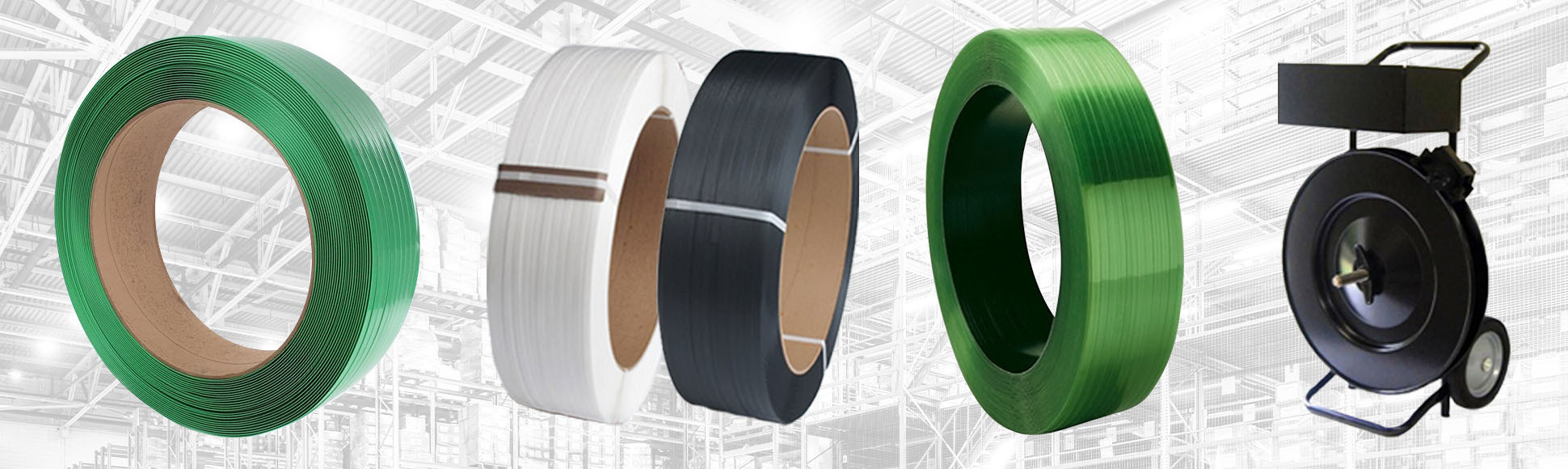

Polypropylene Banding | Polyester Banding | Banding Dispensers Banding Equipment | Tensioners & Sealers

Polyester and polypropylene are two popular materials used for plastic banding. While they both serve the purpose of securing and bundling items together, there are some key differences between the two. See below to learn more.

-

Polypropylene Strapping

Polypropylene Strapping

-

Plastic Strapping Seals & Buckles

Plastic Strapping Seals & Buckles

-

Table Top Semi-Automatic Machines

Table Top Semi-Automatic Machines

-

Polyester Strapping

Polyester Strapping

-

Plastic Strapping Dispensers

Plastic Strapping Dispensers

-

Plastic Strapping Tools

Plastic Strapping Tools

Polyester plastic banding is known for its strength and resistance to stretching. It is often used for heavy-duty applications where high tension is required, such as bundling large construction materials or securing heavy machinery. Polyester banding also has a high break strength, making it a reliable choice for holding together heavy loads. Additionally, polyester banding is resistant to UV rays and weather conditions, making it suitable for outdoor applications.

On the other hand, polypropylene plastic banding is known for its versatility and affordability. It is commonly used for lighter and medium-duty applications such as bundling boxes, packages, or lightweight products. Polypropylene banding is more flexible than polyester, making it easier to handle and work with. It is also available in various colors, which is advantageous for color-coding or branding purposes. However, it is worth mentioning that polypropylene banding may not have the same strength as polyester. It can stretch over time, especially when exposed to prolonged tension or extreme environmental conditions.

In terms of environmental impact, both polyester and polypropylene are recyclable materials. However, polypropylene is more widely recycled due to its lower melting point and higher demand in the recycling market.